RESION Repair Compound PU Adhesive

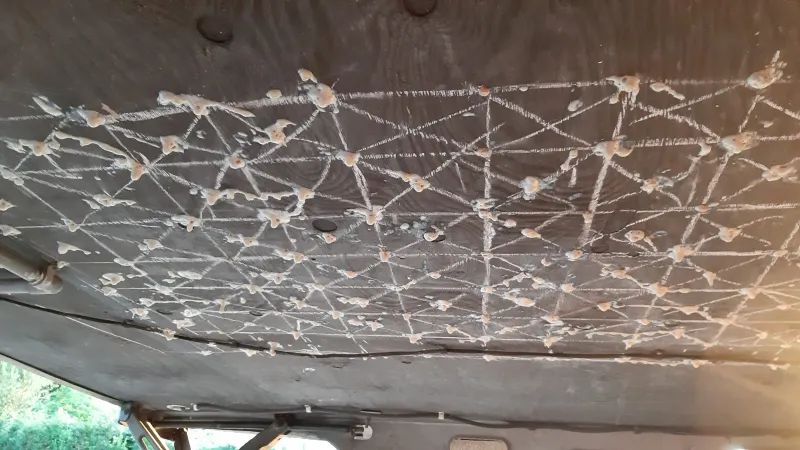

- For repairing caravan floors

- Fast curing

- Compliant with RoHS and REACH

RESION Repair Compound is a fluid, solvent free 1-component polyurethane adhesive, which cures under the influence of moisture. Cure speed is depending on the moisture of the substrate, humuidity of the area, temperature and layer thickness.

- Higher moisture content → faster curing.

- Higher temperature → faster curing.

- Thicker adhesive layer → slower curing.

Features RESION Repair Compound

- Fast curing.

- Shock resistant.

- Flexible.

- Water resistant.

- No solvents.

- RoHS and REACH compliant.

Application

This polyurethane adhesive is especially suitable for wood, rigid PVC, GFK, ABD, foamed polystyrene, PVC, PU, aluminum, steel, RVS, galvanised steel, concrete, stone and combinations, for example: sandwich panels, aluminum insulation panels on polystyrene, asphalt paper on polystyrene and chipboard on polystyrene. Permacol 5663 is often used for injecting caravan floors and is especially suitable for making (sea) water-resistant wood glue constructions (according to EN standard 204-D4, DIN 68602 B4).

Permacol 5663 is not suitable for: glass, polyethylene (PE), polypropylene (PP), polyamide (PA) and polytetrafluoroethylene (PTFE).

Directions for use

To properly apply Permacol 5663 PU Glue, please follow the instructions below:

- Roughen smooth surfaces for better adhesion.

- Make sure the substrates are clean and free from dust, water, grease, fingerprints, oil, etc.

- Sand metals to remove the oxide layer and then clean it thoroughly.

- Apply the adhesive at one side and spread the glue evenly over the surface.

- Press the parts firmly together as soon as possible.

- Now let the glue harden for about 24-48 hours.

Specifications

Contents: 310 ml

Colour (cured): light yellow brown

Viscosity (23°C): 7,000 mPa.s

Density (23°C): 1.10 g/cm3

Application temperature: 15°C-20°C

Ambient humidity (working area): 50%

Wood moisture content: 8-16%

Application gun: sealant gun for cartridges

Open time: 30-60 minutes

Open time (thin layer): 20-25 minutes

Full cure: 24-48 hours

Solids content: 100%

Temperature resistance: -30°C to + 80°C

Consumption: approx. 200 g/m2

Storage stability at 23°C: 6 months in a well-closed original container

We have a number of recommendations for working safely with polymers. At Polyestershoppen you will not only find the polymers themselves, but you can also purchase all the protective equipment you need from us. If you have any doubts or questions, please contact our customer service. We can give you advice on how to work safely with polymers.

RESION Repair Compound | koker 310 ml

Safety equipment

Gevaar

| Code | Description |

|---|---|

| H315 | Causes skin irritation. |

| H317 | May cause an allergic skin reaction. |

| H319 | Causes serious eye irritation. |

| H332 | Harmful if inhaled. |

| H334 | May cause allergy or asthma symptoms or breathing difficulties if inhaled. |

| H335 | May cause respiratory irritation. |

| H373A | May cause damage to organs through prolonged or repeated exposure. |

| H351A | Suspected of causing cancer. |

| P101 | If medical advice is needed, have product container or label at hand. |

| P102 | Keep out of reach of children. |

| P201 | Obtain special instructions before use. |

| P260 | Do not breathe dust/fume/gas/mist/vapours/spray. |

| P314 | Get medical advice/attention if you feel unwell. |

| P308+P313 | IF exposed or concerned: Get medical advice/attention. |

| P405 | Store locked up. |

| P501B | Dispose of contents/container in accordance with in accordance with local regulation |

| EUH204 | Contains isocyanates. May produce an allergic reaction. |