RESION Matt Floor Finish

- Finish for cast floors

- Increases scratch resistance

- Light non-skid

Use RESION Matt Floor Finish as a topcoat for your epoxy cast floor, epoxy floor coating or PU cast floor to protect it against scratches. This matt polyurethane floor coating provides perfect protection for your flooring system while also creating a subtle anti-slip surface for added safety.

The coating is designed to offer durable resistance to various chemicals, including disinfecting alcohol and cleaning agents.

Why choose a matt finish?

A matt floor coating is a smart choice for your cast floor for several reasons. First and foremost, because of its protective properties. Epoxy and polyurethane cast floors are naturally prone to scratches. Our matt coating is specially developed to protect your floor from everyday wear and tear. With this extra protective layer, your floor will stay looking beautiful, even under heavy use.

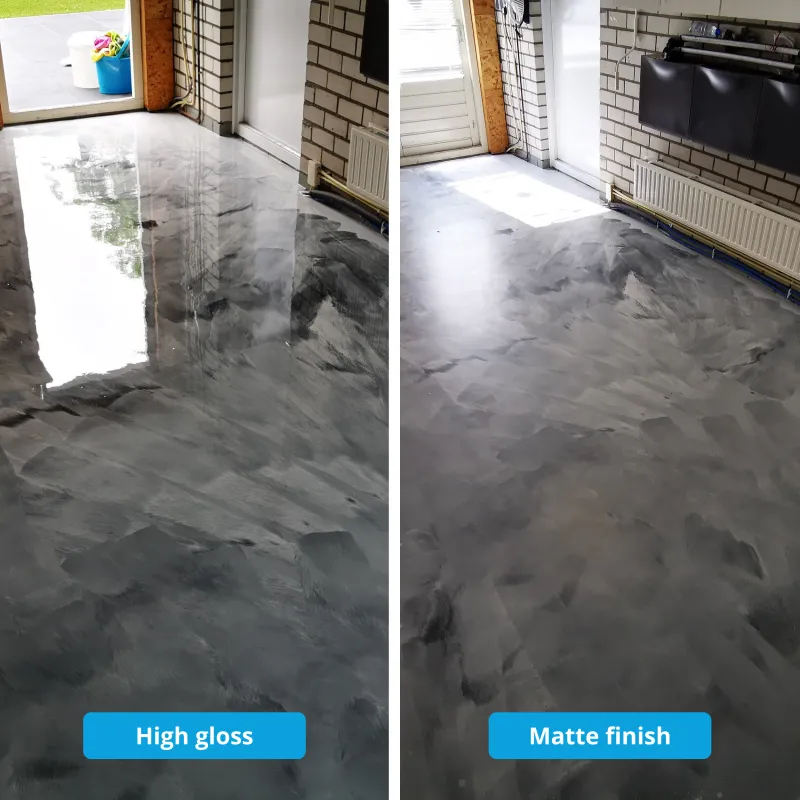

Additionally, epoxy cast floors often have a glossy appearance, which isn’t always desirable. Applying a matt coating creates a stylish, non-glossy surface that complements a variety of interior styles.

Other benefits of this coating

- Resistant to various chemicals.

- Light non-skid properties.

- Excellent elasticity.

- Solvent-free.

Directions for use

RESION Matt Floor Finish is very easy to use. View the brief instructions on this page or refer to the matt floor finish manual for detailed instructions for use.

Before you begin, it is important to ensure the proper application conditions. Allow the floor system to cure for at least 24 hours and no more than 48 hours before finishing the floor with this coating. Make sure the room temperature is between 18°C and 25°C, and that the humidity does not exceed 65%. Clean the floor thoroughly, and ensure it is dry and free of grease before applying the coating.

- Mix both components in a bucket using a mechanical mixer at low speed (approximately 300 rpm). Ensure complete mixing, including the bottom and sides of the bucket. If using less than a full package, maintain a 10:1 mixing ratio by weight.

- Let the coating rest for a few minutes, then pour it through a fine strainer into a clean bucket.

- Apply the floor coating using a short-pile velour roller. Do not pour the mixed coating directly onto the floor; instead, work from a paint tray. Pouring directly makes it impossible to spread the coating evenly.

- Start from the side of the room where the light enters and apply the coating in strips parallel to the window, with a slight overlap (wet-on-wet). Avoid puddles and work systematically, one section at a time, to prevent lap marks. With this coating, it can be difficult to see where you have already applied it.

- Look against the light and roll the strips crosswise evenly to detect and correct any roller marks.

Allow the floor to cure for at least 12 hours before walking on it. Keep in mind that optimal strength is only achieved after 7 days, so handle with care to prevent scratches. If necessary, a second coat can be applied on the same day. Apply the second layer approximately 3 hours after the first coat has cured.

Previously, this product was called 'silk floor coating'. Therefore, this designation is still used in the video.

Specifications

| Packaging | Base (FS402) | Hardener (FS412) |

| 0.55 kg (approx. 6-8 m2) | 0.5 kg | 50 grams |

| 1.1 kg (approx. 12-16 m2) | 1 kg | 100 grams |

| 2.75 kg (approx. 30-40 m2) | 2.5 kg | 250 grams |

| 5 kg (approx. 55-70 m2) | 4.55 kg | 450 grams |

Colour: transparent

Gloss: matt

Base: Polyurethane (PU)

Working time: 4 hours

Dust dry: after 2 hours

Optional second coat: after 3-12 hours (without sanding)

Walkable: after 12 hours

Fully cured: after 7 days

Moisture resistant: after 7 days of curing (at 20°C)

Suitable for: Epoxy Cast floor, PU Cast floor

Not suitable for: car and bicycle tyres (please use RESION PU TyreProof Finish for this)

We have a number of recommendations for working safely with polymers. At Polyestershoppen you will not only find the polymers themselves, but you can also purchase all the protective equipment you need from us. If you have any doubts or questions, please contact our customer service. We can give you advice on how to work safely with polymers.

FS402 | RESION Matte Floor Finish | Base | 0,5kg

Safety equipment

Waarschuwing

| Code | Description |

|---|---|

| H317 | May cause an allergic skin reaction. |

| H412 | Harmful to aquatic life with long lasting effects. |

| P101 | If medical advice is needed, have product container or label at hand. |

| P102 | Keep out of reach of children. |

| P261 | Avoid breathing dust/fume/gas/mist/vapours/spray. |

| P273 | Avoid release to the environment. |

| P280 | Wear protective gloves/protective clothing/eye protection/face protection. |

| P302+P352 | IF ON SKIN: Wash with plenty of water/… |

| P333+P313 | If skin irritation or rash occurs: Get medical advice/attention. |

| P501B | Dispose of contents/container in accordance with in accordance with local regulation |

FS412 | RESION Matte Floor Finish | Hardener | 50 gr

| Code | Description |

|---|---|

| H317 | May cause an allergic skin reaction. |

| H332 | Harmful if inhaled. |

| H335 | May cause respiratory irritation. |

| H412 | Harmful to aquatic life with long lasting effects. |

| P101 | If medical advice is needed, have product container or label at hand. |

| P102 | Keep out of reach of children. |

| P261 | Avoid breathing dust/fume/gas/mist/vapours/spray. |

| P280 | Wear protective gloves/protective clothing/eye protection/face protection. |

| P302+P352 | IF ON SKIN: Wash with plenty of water/… |

| P333+P313 | If skin irritation or rash occurs: Get medical advice/attention. |

| P405 | Store locked up. |

| P501B | Dispose of contents/container in accordance with in accordance with local regulation |

| MDI | As from 24 August 2023 adequate training is required before industrial or professional use |