You can give a metal or pastic surface a fine finish with Double Coat DD Paint. In this article we explain step by step how to do this. DD Paint is a 2-component paint that is very popular in water sports because of its excellent quality, scratch resistance and long gloss retention. In addition, this polyester varnish offers long-term protection against UV light. You can already use DD Paint at temperatures from 15°C.

For an area of approximately 1m2 we used the following products:

On the product pages in our webshop you will find various official downloadable manuals from the manufacturer. Using the five steps below, you can provide metal or plastic surfaces with a beautiful finish.

For optimal adhesion and results, you must first roughen the surface thoroughly and clean it with DD Paint degreaser. Roughening can be done with 400 grit sandpaper. After you have sanded the surface, you can clean it with a cloth and DD Paint degreaser. You can also tape the edges because they do not need to be painted.

To ensure that DD Paint adheres well to the surface, we use ZF primer. This is especially important for metal and plastic surfaces. This step is not strictly necessary for polyester and epoxy substrates.

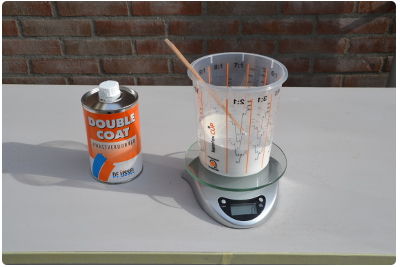

When mixing the primer, it is very important that you maintain the mixing ratio accurately. We therefore recommend always using (digital) scales when mixing the components. Start by mixing the base (component A), because sometimes the pigment has dropped.

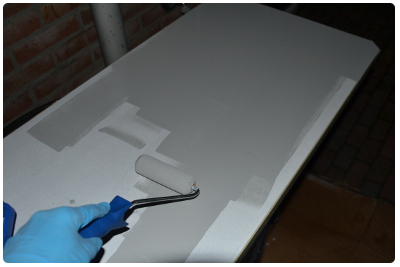

For an area of 1m2 you prepare approximately 200 grams of ZF Primer (150 grams for the product, approximately 50 grams loss). If you close the can properly, you can store unmixed residual product for a long time. Stick to the mixing ratio carefully. If you add too much or too little hardener, this will not have a positive effect on the result. After weighing and mixing the base and hardener thoroughly, pour the contents into a paint container. You can easily apply the ZF Primer with a velour roller. A fully opaque layer is sufficient. Always wear nitril gloves when preparing and processing ZF Primer.

After applying the primer, allow it to cure sufficiently before continuing. The duration of curing depends on the temperature. At 10-15 degrees it is advisable to wait at least 36 hours. We recommend removing the masking tape while the ZF primer is still wet.

Before applying the DD Paint, you must sand the surface once again with a fine grit (400) or Scotchbrite. After sanding, you can clean the surface again with DD Paint degreaser.

After the surface has been properly prepared and cleaned, you can get started with the DD Paint. For proper processing with a foam roller, we recommend adding 5 to 10% brush thinner to the DD Paint. For a surface of 1m2, a total weight of 250 grams is sufficient (200 grams for the surface, 50 grams loss).

Always start by stirring the A component (base). The pigment may have subsided. Pour the basic component (A) into a clean mixing cup and weigh the hardener according to the ratio on the packaging (67:33 parts by weight). Mix everything well and let the Double Coat DD Paint pre-react for half an hour (this is not necessary above 25℃). After half an hour, add 5 to 10% brush thinner. It is important to mix everything thoroughly before pouring it into a paint container.

You can easily apply DD Paint with a foam roller Just as when applying ZF Primer, we recommend always using nitril gloves. Do not use too much DD Paint to avoid streaks and the like.

After you have applied the DD Paint, wait 48 hours before you can load the surface. After 7 days the Double Coat DD Paint has reached its final strength. For even higher scratch resistance, you can apply another layer of DD Paint Double UV after 24 hours.

The photo below shows the end result of the table that we finished with DD Paint high gloss. Do you want a matte or semi gloss? Then use DD Paint satin gloss or DD Paint high gloss. Do you have any questions about the use of the products after reading this article? Please contact our customer service team. Our specialists are happy to provide advice and tips to make your project successful!

Here you can find all 36 related articles on this topic. Mis je informatie om aan de slag te gaan met jouw klus? Neem dan contact met ons op.

Do you have a specific question? Call one of our specialists for free advice +3185 0220090